The spillway gates at Meadowbank Power Station have been in service for more than 50 years, helping to protect the community from floods, keep lake levels constant and the turbine spinning efficiently. Now, the hydraulic cylinders that keep these hard-working gates moving are in need of an overhaul!

The Context

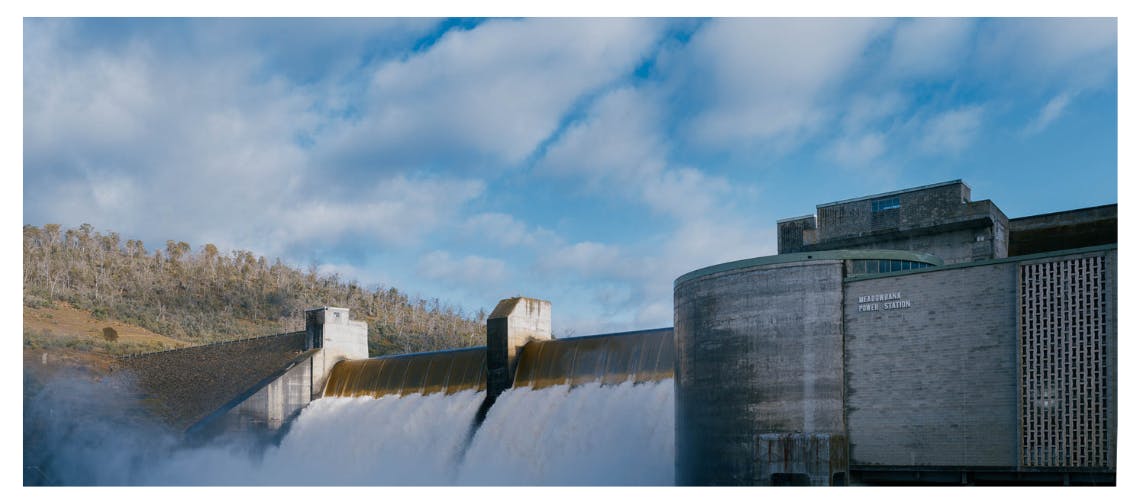

Meadowbank Power Station started operation in 1966. In an average year, it generates 187 gigawatt-hours of electricity, enough to light up Hobart. A common feature of hydroelectric dams is the spillway. There are many different types of spillway but they all share one common purpose – to provide a safe escape route for excess water.

At Lake Meadowbank, the spillway is automatically controlled by 2 crest gates that sit on top of the dam wall. Each gate measures 6 x 35 metres and is controlled by 10 hydraulic cylinders. When the lake is full, these gates hold back approximately 60 million metric tonnes of water! They play a critical role in power generation and safety.

The Issue

We regularly check and maintain all our infrastructure. Over their lifetime, the spillway gates have undergone regular maintenance but now, the hydraulic cylinders and associated piping, wiring and controls need replacing.

At a glance, replacing a hydraulic cylinder (or 20) may sound like a simple task. Hydraulic cylinders are commonplace in industries like construction, agriculture and maritime, and if you're mechanically savvy, you may have even changed one yourself. However, in this context it will be a technically complex and at times hazardous task.

Check out the Technical Project Scope for all the details.

The Solution

The job will start in the workshop. Here, the team will build 2 replica crest gates, fit the new cylinders and put the whole system through a series of real-world simulations. This will be an important opportunity to test the new parts and fine-tune work processes, reducing the risk of future delays.

Once the workshop testing is complete, the team will be ready to head onsite. For the safety of downstream communities and our staff, one gate must always remain operational, so the team will complete the work in 2 stages. Gate 1 will be completed in 2023 and Gate 2 in 2024.

Each stage will be identical, with an installation and testing phase. During installation, the old cylinders and accompanying pipework, electrical wiring and control system will be removed and the new parts fitted. Lake Meadowbank will then be lowered to ensure the gate is dry for comprehensive testing. Once the team has determined the gate is reliably responding to changing water levels, the stage will be complete and the lake will return to its normal level.

Check out the Technical Project Scope for all the details.

We know that since its creation in 1967, Lake Meadowbank has provided an important water source for the surrounding community. Day-to-day, we operate Meadowbank Power Station to keep the lake level relatively constant for the benefit of surrounding water users. From time to time however, lowering the water level is unavoidable to maintain safe and reliable operations.

We have engaged the community early to better understand how they're impacted by this project and what solutions can be put in place to minimise them.

Want to stay up-to-date with this project? Hit the subscribe button to receive news straight to your inbox.

The spillway gates at Meadowbank Power Station have been in service for more than 50 years, helping to protect the community from floods, keep lake levels constant and the turbine spinning efficiently. Now, the hydraulic cylinders that keep these hard-working gates moving are in need of an overhaul!

The Context

Meadowbank Power Station started operation in 1966. In an average year, it generates 187 gigawatt-hours of electricity, enough to light up Hobart. A common feature of hydroelectric dams is the spillway. There are many different types of spillway but they all share one common purpose – to provide a safe escape route for excess water.

At Lake Meadowbank, the spillway is automatically controlled by 2 crest gates that sit on top of the dam wall. Each gate measures 6 x 35 metres and is controlled by 10 hydraulic cylinders. When the lake is full, these gates hold back approximately 60 million metric tonnes of water! They play a critical role in power generation and safety.

The Issue

We regularly check and maintain all our infrastructure. Over their lifetime, the spillway gates have undergone regular maintenance but now, the hydraulic cylinders and associated piping, wiring and controls need replacing.

At a glance, replacing a hydraulic cylinder (or 20) may sound like a simple task. Hydraulic cylinders are commonplace in industries like construction, agriculture and maritime, and if you're mechanically savvy, you may have even changed one yourself. However, in this context it will be a technically complex and at times hazardous task.

Check out the Technical Project Scope for all the details.

The Solution

The job will start in the workshop. Here, the team will build 2 replica crest gates, fit the new cylinders and put the whole system through a series of real-world simulations. This will be an important opportunity to test the new parts and fine-tune work processes, reducing the risk of future delays.

Once the workshop testing is complete, the team will be ready to head onsite. For the safety of downstream communities and our staff, one gate must always remain operational, so the team will complete the work in 2 stages. Gate 1 will be completed in 2023 and Gate 2 in 2024.

Each stage will be identical, with an installation and testing phase. During installation, the old cylinders and accompanying pipework, electrical wiring and control system will be removed and the new parts fitted. Lake Meadowbank will then be lowered to ensure the gate is dry for comprehensive testing. Once the team has determined the gate is reliably responding to changing water levels, the stage will be complete and the lake will return to its normal level.

Check out the Technical Project Scope for all the details.

We know that since its creation in 1967, Lake Meadowbank has provided an important water source for the surrounding community. Day-to-day, we operate Meadowbank Power Station to keep the lake level relatively constant for the benefit of surrounding water users. From time to time however, lowering the water level is unavoidable to maintain safe and reliable operations.

We have engaged the community early to better understand how they're impacted by this project and what solutions can be put in place to minimise them.

Want to stay up-to-date with this project? Hit the subscribe button to receive news straight to your inbox.